Image Processing System

What is an Image Processing System?

Our image recognition system utilizes complex algorithms to extract even the finest features from images, allowing for accurate identification of objects. This technology can be applied to visual inspections (detection of foreign objects, scratches, defects) and counting parts, contributing to reduced manpower on site and improvements in productivity and quality.

Application Examples

- Foreign Object Detection: Used in production line inspections to automatically detect fine foreign objects and impurities.

- Quantity Counting: Accurately counts the number of products or parts on the manufacturing line.

List of Developed Products

-

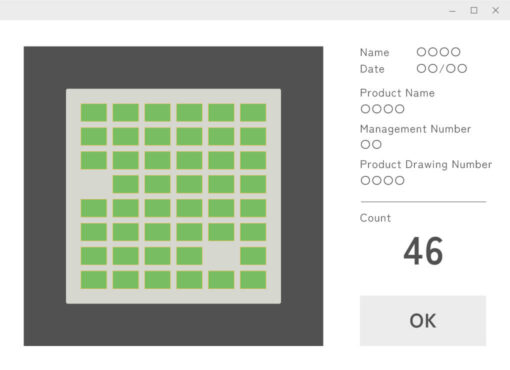

Vision-Based Parts Counter : Automated Component Counting Machine Using Image Sensors

This software counts tens of thousands of uniformly arranged parts of the same type by capturing them with a camera and processing the images. It automates the counting tasks performed during the receipt or dispatch of parts. It is ideal for counting lightweight and small parts that are difficult to measure by weight.

Learn More

-

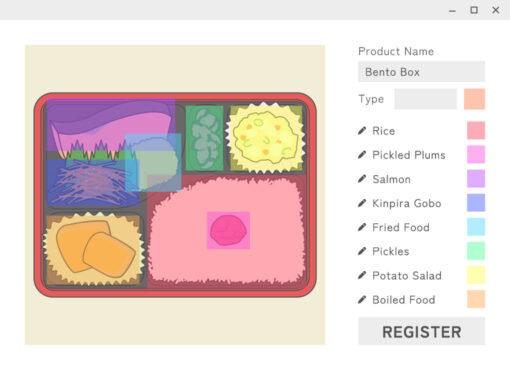

Detecting Missing Ingredients. Bento box Ingredient Inspection Technology.

By capturing images of the bento with a camera and using AI (object detection) and image processing, the system can identify the side dishes in the bento and detect missing items or placement errors within the bento container. AI can also detect variations in individual side dishes. The process of registering the bento with AI is simplified, allowing for compatibility with various containers and side dishes.

Learn More

-

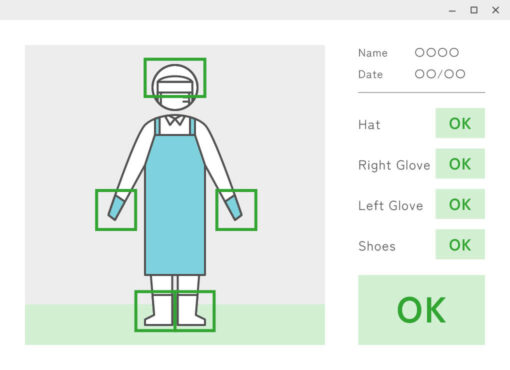

AI Checks the Appearance of Factory Workers: Object Detection Technology for Gloves and Hats

Object detection AI checks items such as gloves and hats and determines their presence or absence, thereby assessing whether workers are dressed appropriately for their tasks.

Learn More