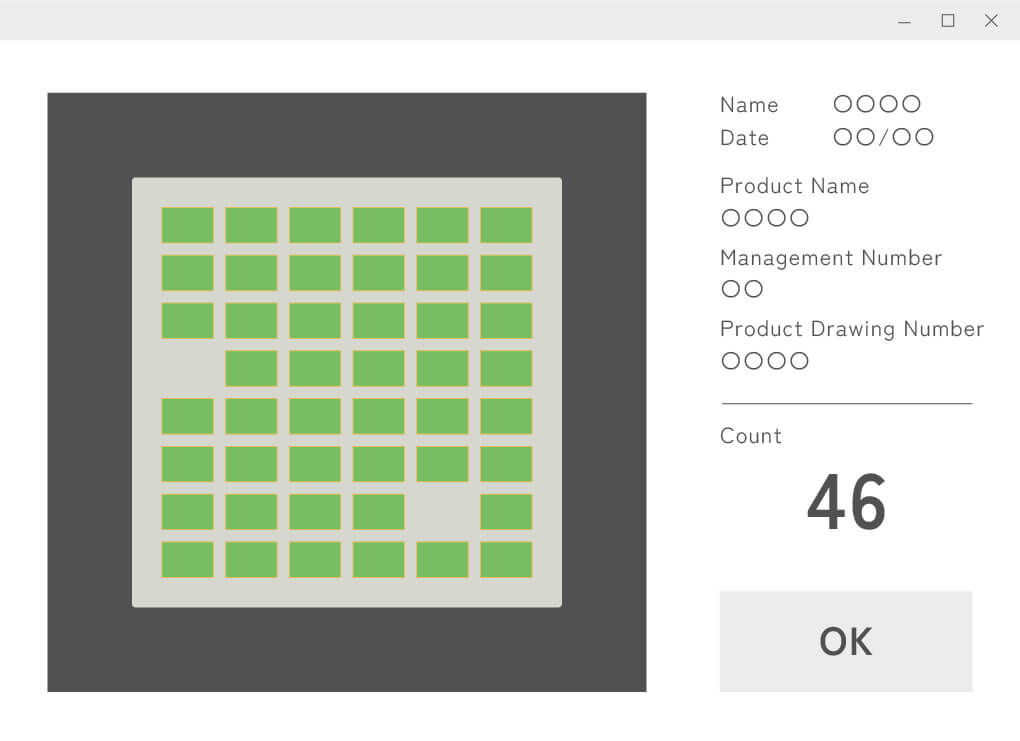

Vision-Based Parts Counter : Automated Component Counting Machine Using Image Sensors

It can capture images of tens of thousands of uniformly arranged components of the same type using a camera and count them through image processing. This system automates the counting process during the receipt or dispatch of components. It is ideal for counting lightweight and tiny components, which is difficult to achieve with weight-based counting.

What Can Be Solved

- Manual counting by human eyes takes a significant amount of time.

- Counting errors occur when using weight measurement.

What Can Be Done

Capable of counting tens of thousands of items at once.

Can count parts as small as 2mm square per piece.

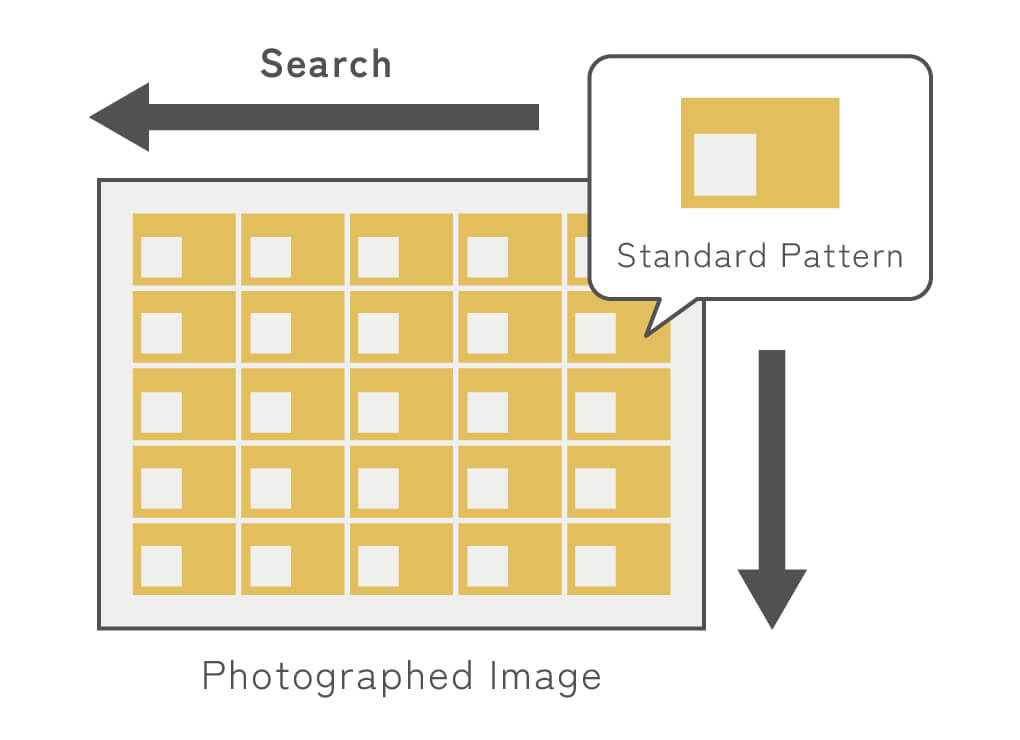

Pattern similarity detection

Based on the patterns on the surface of the parts, the system explores the image, detects parts with matching patterns, and counts their number.

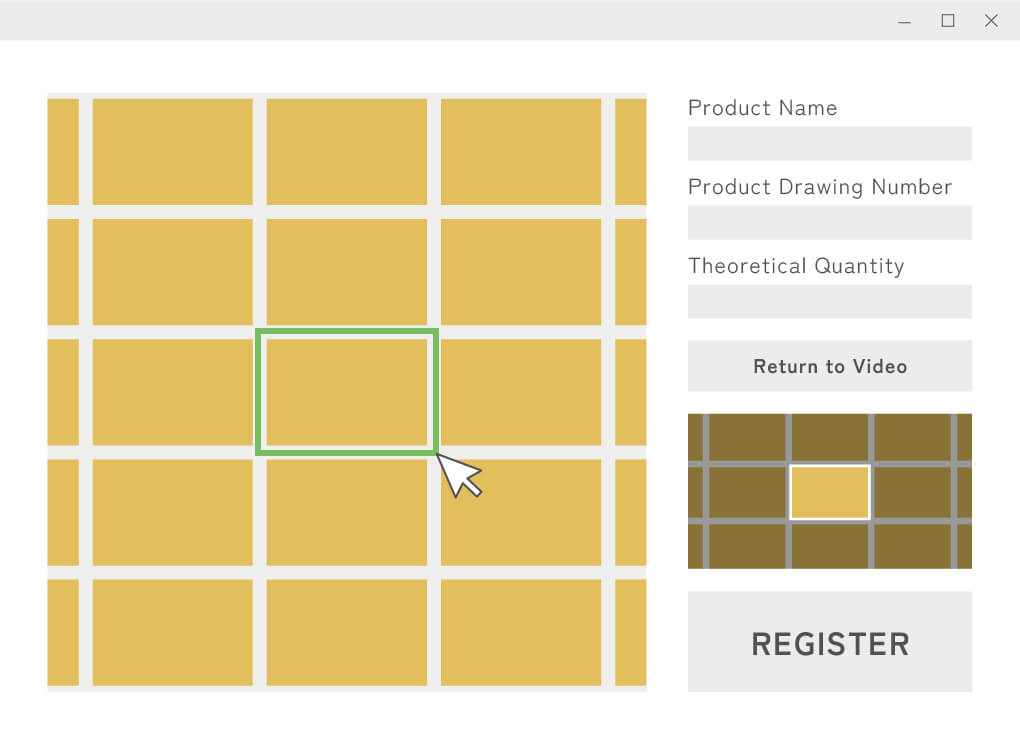

Part registration that takes just 3 minutes

Part registration is completed with just one-time registration of the pattern of the part you want to count.

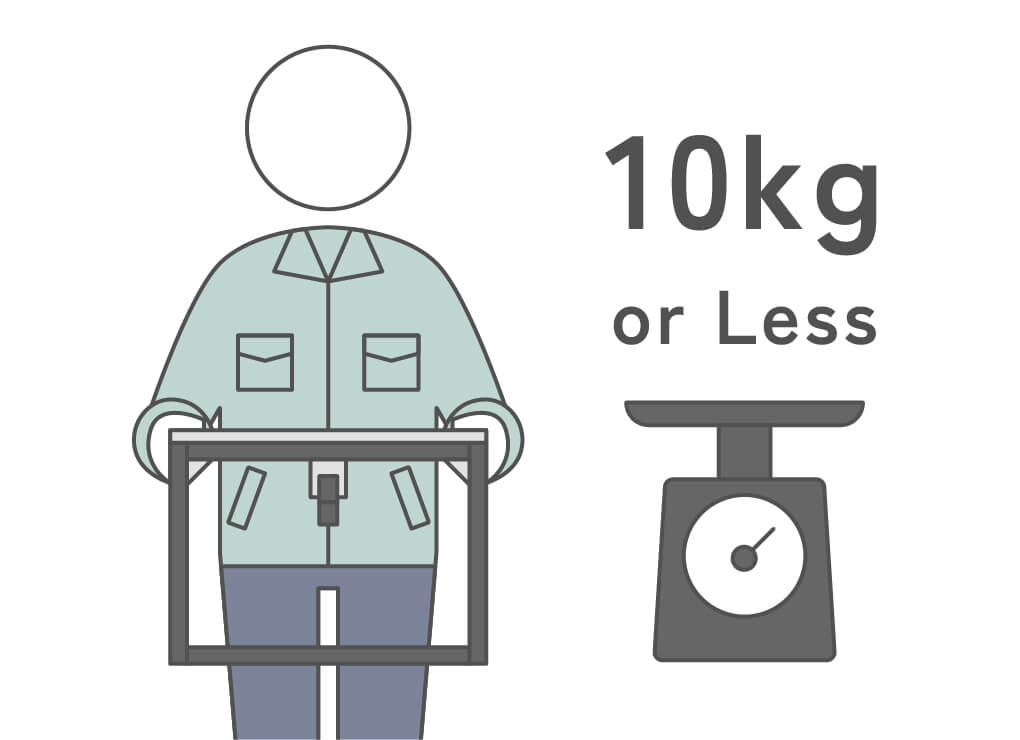

User-friendly equipment

The equipment weighs less than 10 kg, making it easy to move and install by anyone. It features A4-sized lighting and operates on a household power supply.

Countable Parts

-

The parts are uniformly arranged in a grid pattern with consistent spacing both vertically and horizontally.

-

The shape of the parts can be either square or circular.

-

The parts have patterns on their surfaces and are visible to the camera.

Parts that cannot be counted

-

Parts placed randomly and scattered

-

Transparent or translucent parts

Features

-

Count

The camera captures the parts, which are then detected using our proprietary pattern recognition technology to determine the total count.

-

Position and angle correction

As long as the object is within the camera’s field of view, the software automatically corrects for tilt and positioning, even if the object is placed at an angle or near the edges of the frame.

-

Register the expected number

You can register the theoretical quantity as the expected amount and check the difference from the count results.

-

Operator Registration

You can keep a history of who performed the counting.

-

Manual adjustment

If foreign objects like dust, debris, or scraps are mistakenly detected, or if objects covered with foreign matter are not detected, you can correct the count by entering numbers in the fields for false detections or missed detections.

-

Report Output

You can output the counting results in Excel or HTML format by lot.

-

Check Count History

A folder with the date is automatically generated, containing all files including images before and after counting and the counting results. This allows for later review of the contents.

Options

-

Automatic Start of Counting

By default, the user places the counting objects under the camera and starts the count by pressing the start button with the mouse or pressing the Enter key. However, it is possible to configure the system to automatically start counting after a certain period of time once the user removes their hands from the equipment.

-

Multilingual Support

The UI words can be switched to other languages, allowing for multilingual support in the user interface./p>

-

Barcode-based switching

By scanning barcodes or QR codes, you can automatically switch between different product types and languages.